View Mobile Number

jpmachinetools123@gmail.com

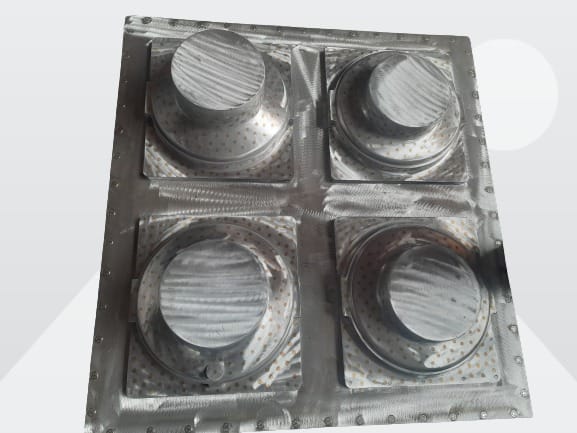

2.50 Lac - 2.75 Lac / piece

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Distributor, Buying House |

| Material | Aluminium |

| Shape | Rectangular |

| Color | Silver |

| Click to view more | |

Product Details

Automation Grade

Manual

Application

Industries

Type

Eps Moulds, PACKAGING TYPE

Thickness

0-15 Mm

Country of Origin

India

Brand Name

J P MACHINE TOOLS

Other Names

EPS MOULD

Payment Terms

L/C, D/A, D/P

Delivery Time

20-25

Packaging Details

J P Machine Tools having all in house facilities to make EPS mould, like aluminum casting on electric furnace and using best grade aluminum alloy to process casting work (Lm-6, 6063 and Hindalco made 99.7 pure aluminum alloy), Design and Development. We make mould in supervision of qualified engineers and skilled person. We do all machining work on VMC to take accuracy and finishing.

We offer EPS mould with perfect shape of packaging and better strength using high quality raw material

We follow below steps to make mould.

Designing of EPS as per drawing/sample/component shape

Make proto sample on VMC for observation finding

All pattern work done by VMC with uniform wall thickness to take more production of EPS

We maintain proper distance to give steam zets to reduce production time

Use proper cooling line in chamber like SS, copper and GI with sprinklers

Do facing of chamber frame for alignment

Heavy Chamber Fabricated with heavy ms strips and all SS bolts

Inspection of mould

We offer EPS mould with perfect shape of packaging and better strength using high quality raw material

We follow below steps to make mould.

Designing of EPS as per drawing/sample/component shape

Make proto sample on VMC for observation finding

All pattern work done by VMC with uniform wall thickness to take more production of EPS

We maintain proper distance to give steam zets to reduce production time

Use proper cooling line in chamber like SS, copper and GI with sprinklers

Do facing of chamber frame for alignment

Heavy Chamber Fabricated with heavy ms strips and all SS bolts

Inspection of mould

J P Machine Tools having all in house facilities to make EPS mould, like aluminum casting on electric furnace and using best grade aluminum alloy to process casting work (Lm-6, 6063 and Hindalco made 99.7 pure aluminum alloy), Design and Development. We make mould in supervision of qualified engineers and skilled person. We do all machining work on VMC to take accuracy and finishing.

We offer EPS mould with perfect shape of packaging and better strength using high quality raw material

We follow below steps to make mould.

- Designing of EPS as per drawing/sample/component shape

- Make proto sample on VMC for observation finding

- All pattern work done by VMC with uniform wall thickness to take more production of EPS

- We maintain proper distance to give steam zets to reduce production time

- Use proper cooling line in chamber like SS, copper and GI with sprinklers

- Do facing of chamber frame for alignment

- Heavy Chamber Fabricated with heavy ms strips and all SS bolts

- Inspection of mould

Looking for "EPS MOULD FOR GEYSER PACKAGING Small 4 CAVITY" ?

Unit

Explore More Products